Rubber compression stress relaxation Tester fabrication|Stress Relaxation : distributing Measuring stress relaxation of rubbers in compression is a key test that is used to estimate the long term sealing behavior and performance life of seals, o-rings and gaskets. 21 linhas · Brasil. 6° no Eliminatórias da Copa. Veja o elenco de Brasil em 2025 na ESPN (BR). Inclui detalhes de jogos, minutos em campo, gols e assistências.

{plog:ftitle_list}

Godsent vs GamerLegion - CS:GO/DOTA2 Matches. Live sc.

compression test arctic cat 800

Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing. Paul Tuckner, Grace Technology & Development. In looking at elastomer testing in general and CSR testing in . Measuring stress relaxation of rubbers in compression is a key test that is used to estimate the long term sealing behavior and performance life of seals, o-rings and gaskets.

The most important factor in achieving good repeatability and reproducibility when making stress relaxation tests is to keep the compression constant during all measurements. The two cycling test methods specified are designed to carry out the following: — age the test piece by stress relaxation and determine the sealing force at low temperatures Compression Stress Relaxation (CSR) continues to be an important attribute in the evaluation of materials and seal configurations for their ability to provide sealing force retention under a range of conditions. . Oils, Fluids and Thermoplastics-SP-1611, SAE 2001 Transactions Journal of Materials & Manufacturing-V110-5 Related Topics .Compression stress relaxation testing on vulcanized and thermoplastic rubber; Video 01: Creep Test. Start Material Testing. . Experience in hardware design, cost optimization, and high-volume manufacturing operations. Ph.D. . Experience with compression stress relaxation measurement was not particularly widespread when the ISO standard was first formulated, a variety of apparatus was in use and reproducibility was not good. . Test methods for rubber ‘O’ rings. Google Scholar ASTM F36, 2015. Compressibility and recovery of gasket material. Google Scholar ASTM .

compression test astm d395

Manufacturing industry; Management Systems; Mining; Utilities; Oil, Gas and Chemicals; . This sealing pressure is decreasing in time at constant compression or tension due to stress relaxation of the rubber material. At the moment that the sealing pressure in the rubber is decreased by relaxation until a critical level, the rubber part will .Compressive Stress Relaxation. Compared to the compression set test, the compressive stress relaxation doesn’t evaluate the elastic recovery of a material after stress relief but the preservation of the sealing force at a constant deformation.Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression — Part 1: Testing at constant temperature . Caoutchouc vulcanisé ou thermoplastique — Détermination de la relaxation de contrainte en compression — Partie 1: Essais à température constante . This is a preview of "ISO 3384-1:2011". 5.2 The ability of a material to relax at high-stress concentrations such as are present at notches, inclusions, cracks, holes, and fillets can be predicted from stress-relaxation data. Such test data are also useful to judge the heat-treatment condition necessary for the thermal relief of residual internal stresses in forgings, castings, weldments, machined or cold .

The extracellular matrix and most tissues are stress relaxing, and the kinetics of stress relaxation have been recognized as an important mechanical cue that affects the migration, proliferation, and differentiation of embedded cells. [2] Stress relaxation calculations can differ for different materials: To generalize, Obukhov uses power . Measuring stress relaxation of rubbers in compression is a key test that is used to estimate the long term sealing behavior and performance life of seals, o-rings and gaskets. Many of these components are used in safety critical applications and must operate without failure for their expected lifespan in often demanding environmental conditions.

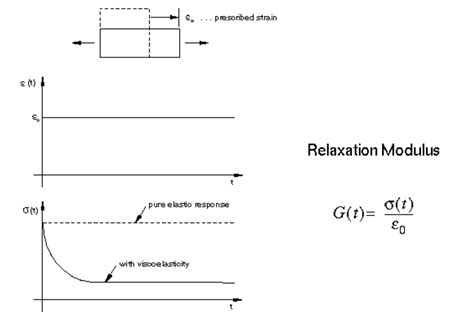

Our rubber and plastic testing experts have years of experience conducting accelerated aging testing to industry standards and custom specifications. Common Standards for Stress Relaxation Testing. ASTM D6147—Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation) in CompressionRubber, vulcanized or thermoplastic - Determination of stress relaxation in compression - Part 1: Testing at constant temperature This document specifies two procedures for determining the decrease in counterforce exerted by a test piece of vulcanized or thermoplastic rubber which has been compressed to a constant deformation and maintained . Testing for Compression Set. Several test methods exist for quantifying the compression set of elastomers. Two common test methods are ASTM D-395 and ASTM D-1414. Both test methods use the same test apparatus, but different test specimens. A constant deflection test apparatus is shown below. The test procedure is as follows: 1.)but decreases with time; this behaviour is called “stress relaxation”. Conversely, when rubber is subjected to a constant stress, an increase in the deformation takes place with time; this behaviour is called “creep”. Tests in compression are normally made under continuous stress conditions (i.e. the test piece remains

Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression — Part 1: Testing at constant temperaturegiven time during a stress relaxation test. 3.1.5 relaxed stress—the initial stress minus the remaining stress at a given time during a stress relaxation test. 3.1.6 stress relaxation curve—a plot of the remaining or relaxed stress as a function of time. 3.1.6.1 Discussion—A curve to demonstrate that the stress relaxation behavior can be .

The simulated stress relaxation rate of the average contact stress on the upper surface of the rubber sealing gasket is 51.0%, and the stress relaxation rate of test results is 50.4%. The difference between them is 0.6%, which shows that the material parameters selected in this paper are reasonable, and the constitutive model can well simulate .

were detached for compression set test and stress relaxation test at 25% strain levels individually at room temperature for every selected time. The test procedure follows the GB/T 7759.1-2015 and GB/T 1685-2008 standards. The data obtained in this study may be used to investigate the effect of different operating conditions, acids,The Compressive Stress Relaxation Test (DIN) ISO 3384-1 describes two methods for determining stress relaxation under pressure. In addition, the American SAE J 2979 also defines tests for compressive stress relaxation. An elastomer specimen is compressed with a constant load and the force it exerts against this external influence is measured. scope: This document describes test procedures and conditions for determining the loss in counterforce of a standard specimen shape compressed at a constant deformation in specified media, under conditions of time and temperature. It is designed for testing of (a) specimens of vulcanized rubber, and thermoplastic elastomers with instantaneous Shore A . Minimizing creep and stress relaxation is a key consideration when designing elastomeric parts. . A rubber band is a familiar example of an elastomer subjected to tensile forces. Another is the soft plastic bumper on a cellphone case, which when subjected to a compressive force of a drop or blow deforms to protect the phone from shock, and .

The most important Stress Relaxation test on rubber products determines several years of lifetime endurance. Test buttons are made from rubber products. Samples preparation must be done with extreme care. Tests are as per EN 681 Standards. Preparation of test buttons out or rubber products for a given production batch is of utmost importance. This article describes .Figure 2. Stress Strain curve of the instantaneous elastic response of the rubber defined by means of a Neo-Hooke strain energy potential. 2. Figure 3 shows the time-dependent behaviour of the rubber evaluated though a stress relaxation test at 5% strain. The material will be modelled with a linear The use of ring test pieces is particularly suitable for the determination of stress relaxation in liquid environments. This document deals only with testing at constant ambient or elevated temperature. Testing at temperatures below standard laboratory temperature is .

Measuring Compression Set of Solid Elastomers. Most compression set testing follows ASTM D395, Test Method B. Solid elastomer specimens 0.25″ thick x 0.52″ diameter are compressed to 0.177″ thick using a device as diagrammed, for 22 to 70 hour periods at elevated temperature in an air circulating oven. Compression set represents the percent of deflection that did not return.the commencement of that time-interval. (Stress relaxation is a synonym.) 4. Summary of Test Method 4.1 Method A—The test specimen is compressed at the test temperature, and it is maintained at this temperature through-out the test period, all force measurements being made at the test temperature. 4.2 Method B—The test specimen compression .

given time during a stress-relaxation test. 3.2.4 spherometer, n—an instrument used to measure circu-lar or spherical curvature. 3.2.5 stress-relaxation curve, n—a plot of either the remain-ing time or relaxed stress as a function of time. 3.2.6 stress-relaxation rate [FL−2 T–1],n—the absolute value of the slope of the stress .

Test methods for compression stress relaxation –

Stress Relaxation

Compression stress relaxation (CSR) testing:

Acesse o aplicativo do Globoplay na sua Smart TV; No menu do lado esquerdo, selecione Minha Conta e em seguida clique no botão " Entrar "; Escolha uma alternativa para .

Rubber compression stress relaxation Tester fabrication|Stress Relaxation